02 August 2021

Improved transparency, reduced delay in GRV distribution and higher efficiency – all of which can be achieved with an automated goods received voucher.

In the past, a typical day at our North Riding Warehouse included receiving cargo at the warehouse, conducting a material inspection, counting and measuring cargo weight and dimensions, returning to the office, commencing with the manual goods receipt process, printing all paperwork, binding the GRV with the delivery note, scanning documentation and manually sending it to the customer. This time-consuming and inconvenient process might sound familiar to the vast majority of the transport and logistics industry. However, at Alistair Group we constantly look for ways to remove bottlenecks and improve our efficiency.

The goods received voucher (GRV), also known as a goods received note (GRN), was oftentimes reported to our team as being a problem area; taking anywhere between two to four days to deliver. This paperwork intensive process was flying under our efficiency radar and costing our business a lot of time and effort to manually process. GRV’s play a key part in notifying customers that their cargo has successfully been delivered. Without a timely and accurate GRV, our customer’s processes are delayed; BV inspections and load planning is stalled and thus transport of goods to the final destination is set back. Whilst auditing our GRV process, in the subsequent discussion with our warehousing team, it was made evident that manually processing the GRV took a large amount of time in data entry and distribution to customers. Additionally, our current process allowed for things such as human error, lack of accuracy, delays in sending the GRV and the inclusion of multiple unnecessary steps. Staff often had to walk more than 300m to book a goods receipt.

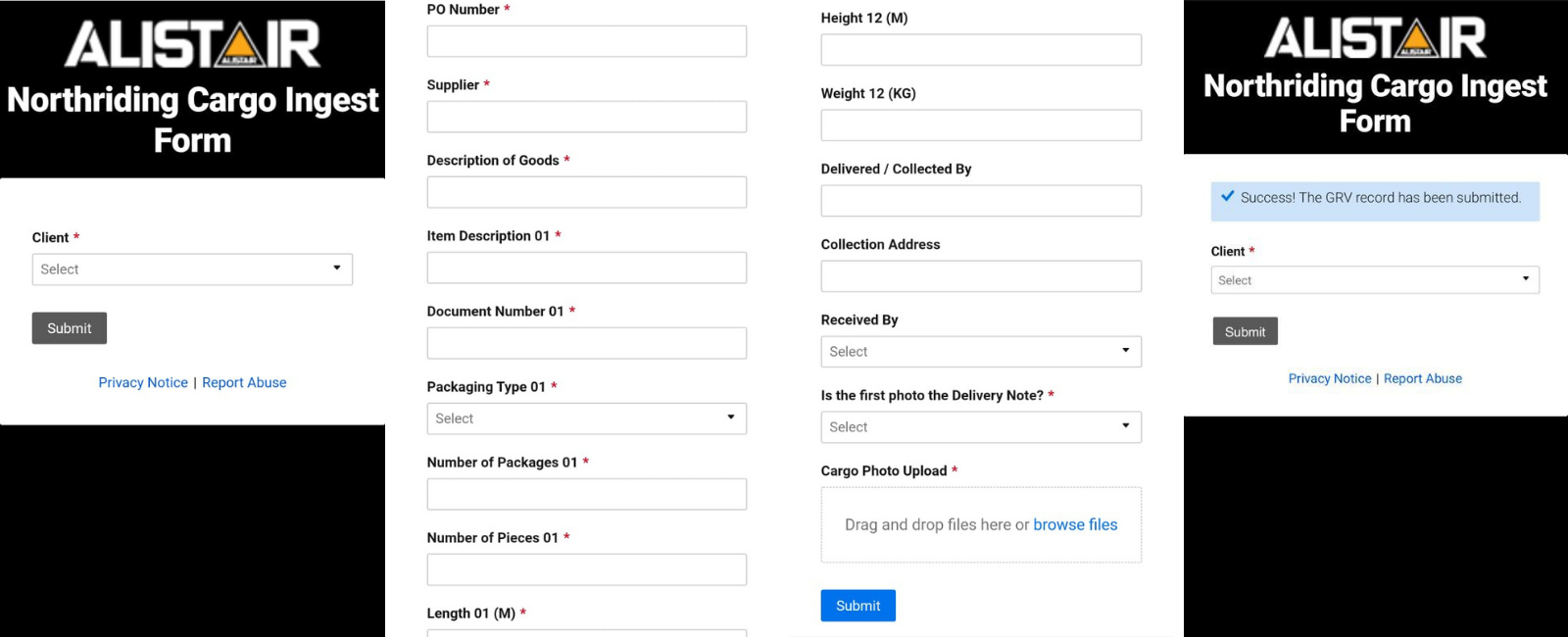

It was these conditions that led Alistair Group to develop and introduce an automated GRV system. The countless back and forth to receive cargo in the warehouse and input the data at the office, all of which was captured manually, has now been replaced with a user-friendly web-based application (see screenshot below). Our staff are now able to utilise their mobile phone or the office tablet to immediately capture all information while with the cargo. Thus, data entry can be done on-sight as soon as the cargo arrives; resulting in real-time data capturing and delivery transparency to customers.

The new application is equipped with predetermined fields, automated customer information, cargo and delivery-note photo capturing and uploading capabilities, automatic GRV distribution and dashboard delivery status updates. This allows staff to book the cargo much faster. Through this improvement, Alistair Group has been able to make a substantial leap in the digitalization and automation of delivering GRV’s. Reducing the goods receipt process and drastically shortened the GRV delivery time; now allowing us to deliver GRV’s to customers within ten minutes of cargo delivery. The same data which is captured in the GRV note is then used to automatically prepare further documents such as Road Consignment Notes, Packing Lists and Clearance Documentation.

2021 marks 13 years of Alistair Group; a significant milestone for a company that began with one truck and the desire to solve problems. As of today, Alistair Group is the preferred logistics provider for a vast majority of industries in South and Eastern Africa. The Group operates across 20 countries worldwide, employs over 800 staff, manages 1039 assets and has 18 offices across Africa.

2021 marks 13 years of Alistair Group; a significant milestone for a company that began with one truck and the desire to solve problems. As of today, Alistair Group is the preferred logistics provider for a vast majority of industries in South and Eastern Africa. The Group operates across 20 countries worldwide, employs over 800 staff, manages 1039 assets and has 18 offices across Africa.